5 Layer Blown Film Machine: Types, Benefits, and How to Choose the Right One

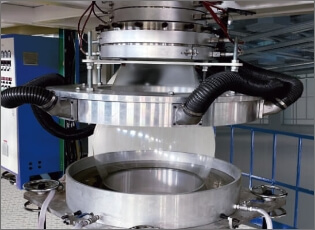

What is a Five Layer Blown Film Machine?

Five-layer blown film machine also known as five-layer co-extrusion blown film machine is an advanced co-extrusion technology designed for the production of high-performance films with excellent barrier properties, flexibility and strength. It is commonly used in food packaging, medical film, industrial applications, and agricultural films. This technology enables manufacturers to combine different polymer layers to achieve superior film properties and optimize blown film production efficiency.

Five Layer Blown Film Machine Types and Applications

Blown film machines are categorized based on their applications and structural designs. The three most common types of Five Layer Co-Extrusion Blown Film Machines are :

-

POD Blown Film Machine

Structure and Properties

POD (Polyolefin-Dedicated ) technology processes LDPE, LLDPE, and HDPE materials with precise layer control. With more layers, film has better physical properties with thinner structure, which means the factory can save raw material. The Five Layer Blown Film Production Process enables better material utilization and quality control.

Applications

- PE Printing/Lamination Film – Used in high-quality flexible packaging.

- Shrink Film – Ideal for bundle packaging with high transparency, such as PE heat shrink film.

- Agricultural Films – Includes greenhouse films and silage films with enhanced durability. Moisture-proof and UV-proof would be important factors.

Advantages

- Eco-Friendly: Mono-material structure makes it easy to recycle.

- High Performance: Excellent tear resistance, heat sealing, and durability make it suitable for high-speed packaging equipment.

- Cost Optimization: Lower raw material costs compared to multi-material films.

Future Development

- Innovation in Polyolefin Materials – Oriented POD film would enhance[9] barrier properties to replace multi-material barrier films.

- Sustainability – Improving recyclability and integrating circular economy concepts.

-

Barrier Blown Film Machine

Structure and Properties

A high-barrier middle layer (EVOH, PA) [10] improves gas and moisture resistance, making it ideal for food and medical packaging. Outer PE layers protect barrier layers from liquid and at the same time, improve processability such as heat sealing. The Five Layer Blown Film Extrusion Process ensures consistent film quality with enhanced protection properties.

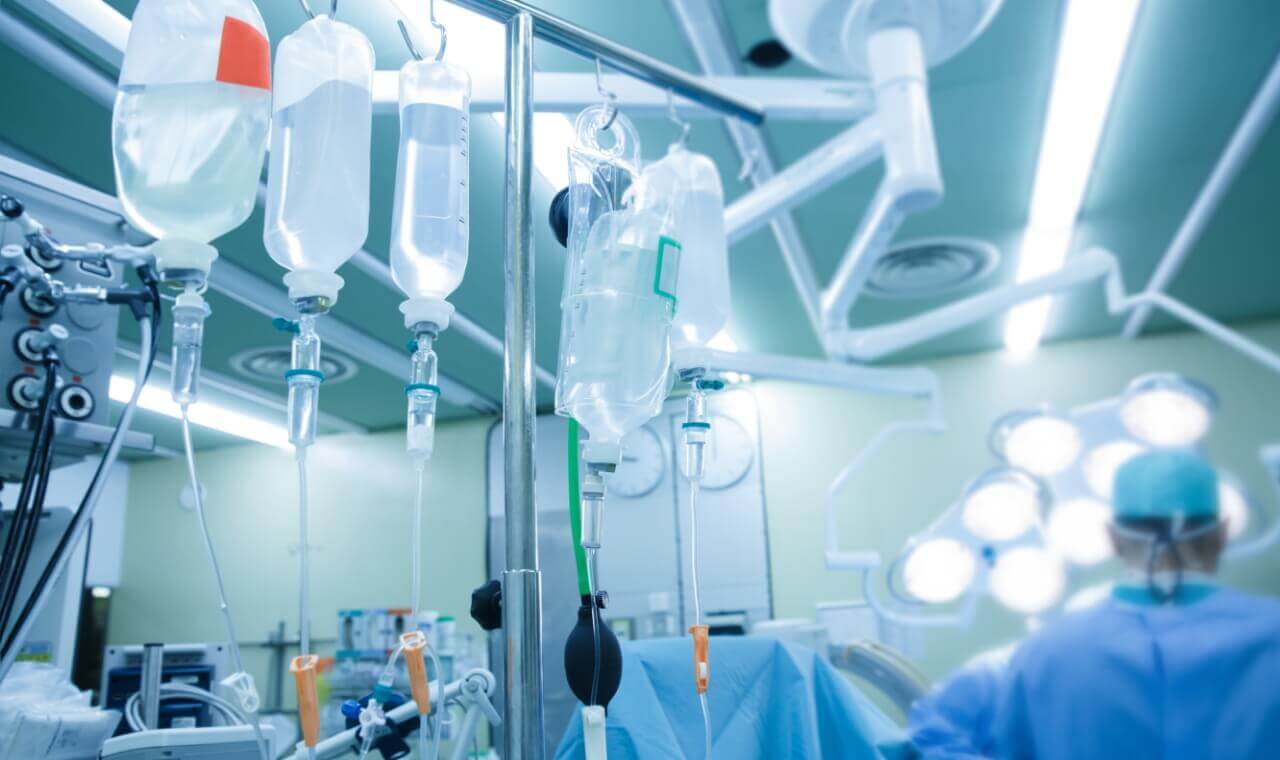

Applications

- Food Packaging – Used in long-term preservation such as vacuum-sealed and frozen food packaging.

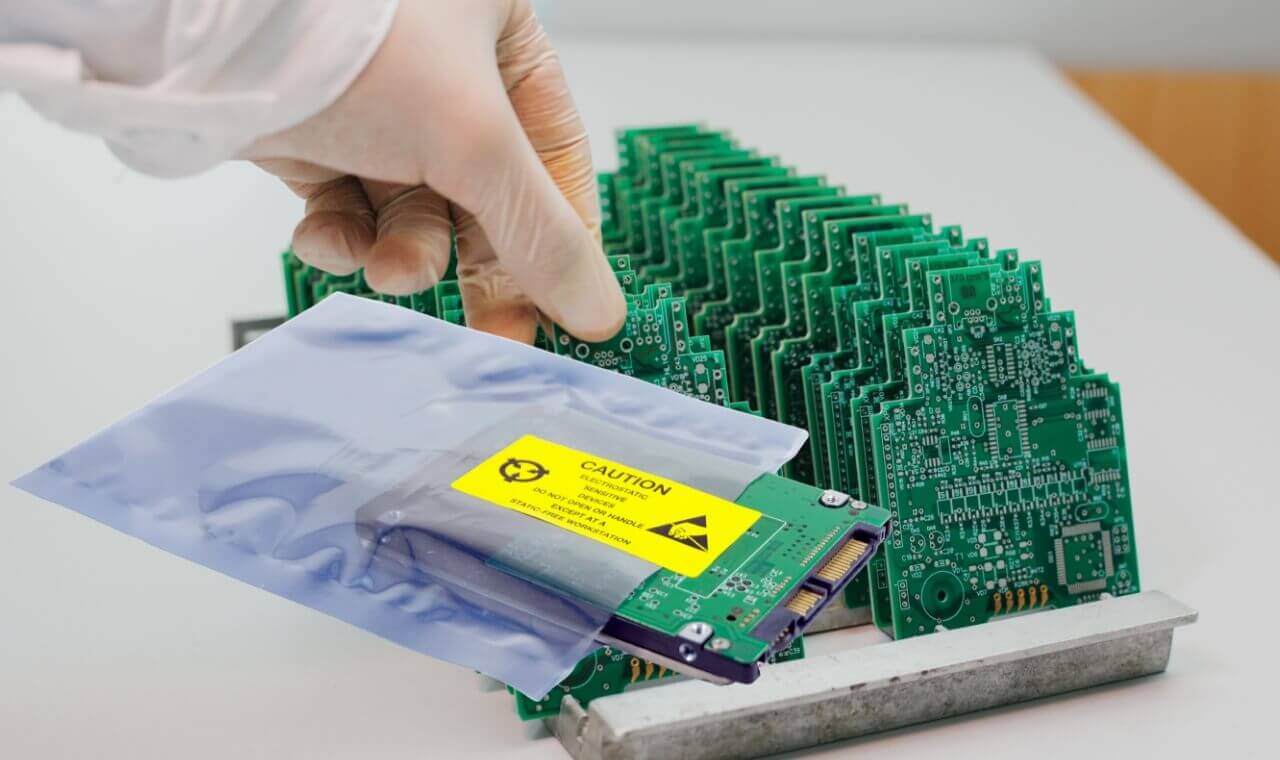

- Industrial Packaging – Protects chemical products and electronics from moisture and oxidation.

- Medical Films – Sterile packaging for medicines and medical devices.

- Lamination Films - Laminated with other films for a multi-purpose packaging.

Advantages

- Excellent Barrier Properties: Extends product shelf life.

- Flexible Multi-Layer Design: Customizable thickness and composition.

- Material Efficiency: Reduces overall material consumption compared to lamination processes.

Future Development

- Advanced EVOH Materials – Enhancing oxygen barrier while reducing material thickness.

- Expanded Applications – Adapting for autoclaving, freezing, and microwave-safe packaging.

- Smart Manufacturing – Real-time production monitoring to improve efficiency.

-

MDO Blown Film Machine

Structure and Properties

MDO (Machine-Direction Orientation) technology stretches film in the mechanical direction, improving strength, clarity, and cost efficiency. The Five Layer Blown Film Machine Production Process incorporates precision stretching techniques - which includes four stages of pre-heating, stretching, heat setting and cooling for optimal film performance.

Applications

- Packaging Films – Used for food and pharmaceutical packaging.

- Industrial Films – Suitable for labels and tape substrates.

Advantages

- Performance Enhancement: Higher tensile strength, transparency, gloss[15] and improved printability.

- Cost Savings: Produces thinner yet stronger films.

- Eco-Friendly: Supports mono-material recycling for sustainable packaging.

Future Development

- Material Innovations: Developing heat-resistant and anti-fog MDO films.

- Automation Integration: Implementing AI-driven quality control for higher production efficiency.

How to Choose the Right Five Layer Blown Film Machine

When selecting a Five Layer Blown Film Machine, consider these key factors:

- Target Applications: Do you need high-barrier packaging, shrink film, or industrial films?

- Material Compatibility: Can it process LDPE, LLDPE, HDPE, PP, EVOH, and PA?

- Production Efficiency: Does it support high-speed, high-output operations?

- Cost Considerations: Compare initial investment vs. long-term ROI.

- Sustainability Goals: Does it align with eco-friendly production trends?

- Technical Supports: Do you have skilled operators in your factory to manage 5- layer blown film line?

Benefits of Using a Five Layer Blown Film Machine

- Improved film strength, clarity, durability and barrier properties.

- Greater customization flexibility for different industries.

- Lightweight and economical by producing thinner films.

Five Layer Blown Film Machine vs Three-layer and Seven-layer Film

- Three-layer films are cost-effective but offer limited barrier performance.

- Five-layer films balance cost, barrier, and mechanical properties.

- Seven-layer films provide ultra-high barriers but at a higher cost.

Industries commonly use Five Layer Blown Film Machines

- Food & beverage packaging

- Industrial & medical packaging

- Agriculture & construction films

Is a Five Layer Blown Film Machine Right for You?

A Five Layer Blown Film Machine, or 5 Layer Co-Extrusion Blown Film Machine, is a powerful solution for manufacturers looking to improve film strength, flexibility, and barrier properties. By selecting the right machine and optimizing material compositions, businesses can enhance product performance and sustainability, making it an ideal investment for high-quality blown film production.

To further understand barrier film technology and its impact on film performance, explore our articles on:

- Barrier Film Machines: How Blown Film Technology Enhances Barrier Performance

- High-Barrier Packaging Films and Advanced Barrier Film Machinery

If you're considering a Five Layer Blown Film Machine for your production line, our team is here to help! Contact us today to get expert guidance and customized solutions tailored to your needs.