Barrier Film Machines : How Blown Film Technology Improves Packaging Performance

When packaging requires superior protection against oxygen, moisture, or UV light, barrier packaging films are the ultimate solution. At Horng Tair Industrial, we specialize in multi-layer barrier film machines and high barrier blown film extrusion systems, helping manufacturers in food, medical, and industrial sectors achieve unmatched quality, efficiency, and precision.

What Are Barrier Film Machines?

Understanding the Basics of Barrier Film Machines

Barrier film machines are specialized systems designed to produce films with exceptional protective properties. These machines are critical for industries such as food packaging, pharmaceuticals, and healthcare, where preserving product integrity is paramount.

To understand their operation, let’s examine the key components that ensure consistent barrier performance:

Key Components of Barrier Film Machines:

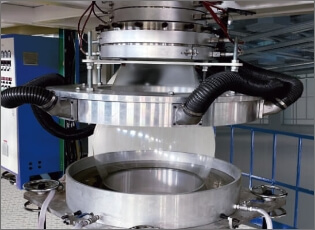

A multi-layer barrier film machine consists of critical components that work together to deliver precise and consistent results. Each plays a crucial role in ensuring the final film ]achieves the required barrier properties.

- Extruder: Melts and mixes the raw polymer materials.

- Die: Shapes the polymer into a tubular film, forming the foundation for the barrier structure.

- Cooling System: Cools the film bubble to ensure consistent thickness and quality.

- Control Units: Facilitate precision adjustments for temperature, layer distribution, and pressure.

With these components working in harmony, barrier film machines create films that are not only durable but also versatile enough to meet various industrial needs.

Blown Film Technology: Process and Applications

Blown film technology is at the heart of barrier film production. This process combines advanced materials and precision engineering to create films tailored for specific applications.

How It Works:

- Melting: Polymer pellets are melted in the extruder.

- Forming a Bubble: The molten material is extruded through a die, forming a tubular bubble.

- Cooling and Flattening: The bubble is cooled and flattened into rolls of film.

Material Versatility: Blown film technology supports a wide range of polymers, including LDPE, HDPE, and specialty resins, enabling customizations for diverse applications.

Why It’s Ideal for Barrier Films: The process allows for multi-layer co-extrusion, combining different materials into a single film to optimize properties like oxygen resistance and moisture protection.

With this foundation established, it becomes clear how blown film technology plays a central role in enhancing the barrier performance of modern packaging films.

How Blown Film Technology Enhances Barrier Performance

The true advantage of blown film lies in its ability to improve and optimize film characteristics. Here’s how the process strengthens barrier properties in practical applications.

-

Multi-Layer Co-Extrusion:

Blown film machines allow the creation of multiple layers, each serving a unique purpose—such as improving sealability or blocking light. For example, a 7-layer high barrier film might feature layers for moisture resistance, oxygen barrier, and heat-seal properties.

To learn more about the advanced co-extrusion processes and materials that make this possible, explore our article: High-Barrier Packaging Films and Advanced Barrier Film Machinery: Applications and Innovations.

-

Precision and Consistency:

Uniform film thickness ensures reliable performance, especially for high-barrier applications. Advanced control systems maintain consistency across production batches.

-

Customizable Film Properties:

Tailor films for specific needs, from high-strength industrial packaging to biodegradable, eco-friendly options.

To deliver these advantages at scale, Horng Tair Industrial has developed advanced machine configurations that meet today’s demanding production requirements.

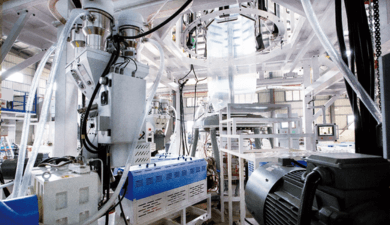

Horng Tair Industrial: Advanced 5-Layer and 7-Layer Blown Film Machines

At Horng Tair Industrial, innovation goes hand in hand with proven engineering. Our 5-layer and 7-layer blown film machines are designed to serve a wide variety of packaging applications with unmatched precision and efficiency.

Real-World Applications and Success Stories

The benefits of barrier film machines are best illustrated through real-world use cases. From food to healthcare, these solutions help businesses meet stringent standards while reducing waste.

-

Food Packaging

: A multinational brand used 5-layer high barrier packaging films produced on Horng Tair’s blown film machines, extending shelf life by 30% and reducing food waste. -

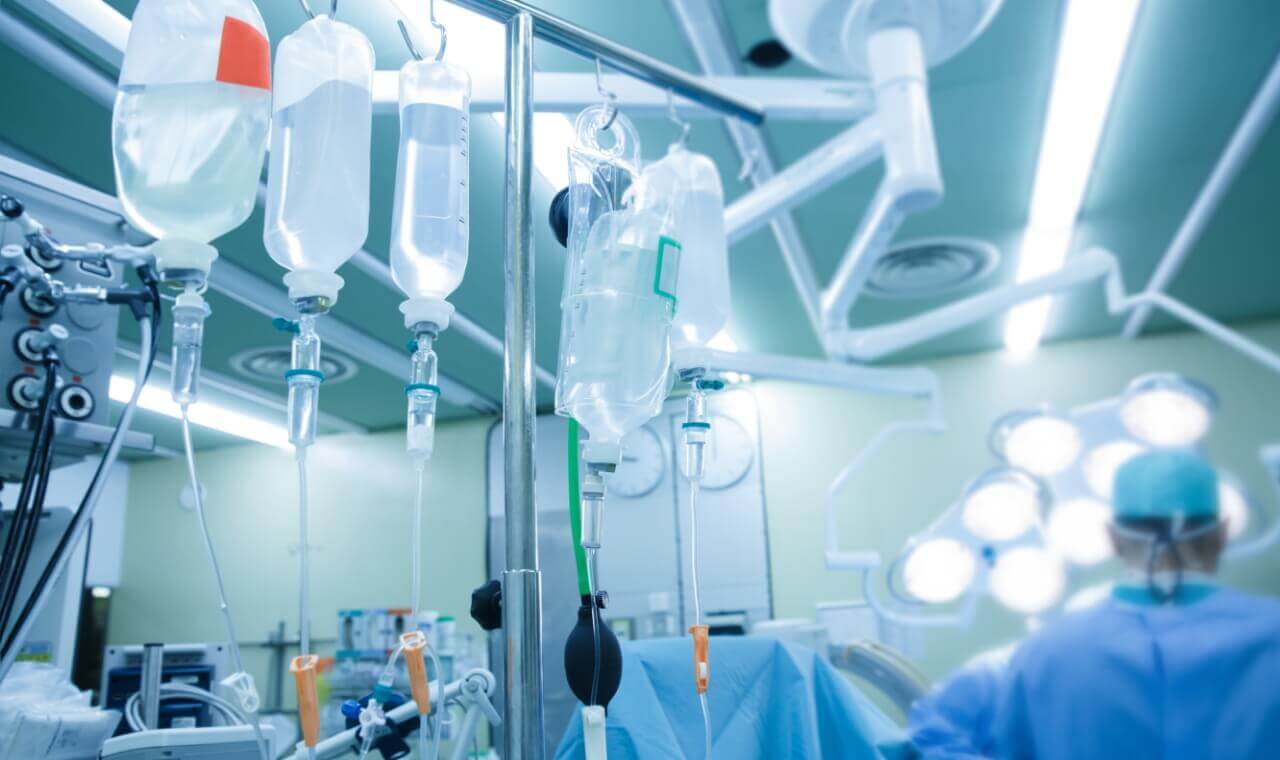

Healthcare

: Leading medical suppliers adopted 7-layer barrier extrusion machines, ensuring sterility of sensitive products and full compliance with international regulatory standards.

Future Trends in Blown Film and Barrier Film Technology

As industries evolve, so does packaging technology. Barrier film machines will continue to advance, offering new opportunities and challenges for manufacturers.

-

Emerging Innovations

: New materials and advanced co-extrusion techniques are reshaping the possibilities for barrier films. -

Automation and AI

: Smart technologies enhance production precision and operational efficiency. -

Sustainability Shifts

: With rising demand for eco-friendly packaging, manufacturers are moving toward recyclable barrier films and biodegradable multi-layer packaging solutions. Future high barrier film extrusion machines will also integrate energy-saving systems to reduce carbon footprint.

With these exciting developments on the horizon, manufacturers will need reliable partners to stay ahead of the curve.

Partner with Horng Tair Industrial for Advanced Packaging Solutions

With rapid industry changes ahead, choosing the right partner ensures long-term competitiveness. Horng Tair Industrial is committed to delivering state-of-the-art barrier film machines that meet today’s challenges and tomorrow’s opportunities.

Ready to elevate your packaging capabilities with advanced multi-layer barrier film machines? Contact Horng Tair Industrial today for a consultation and discover how our high barrier blown film extrusion systems can transform your production process.